Forged aluminum is crucial in applications needing strong performance because of its capacity to tolerate high stress and fatigue, and its resistance to corrosion guarantees longevity in challenging conditions. All things considered, forged aluminum helps various industrial sectors operate better, save fuel, and perform better.

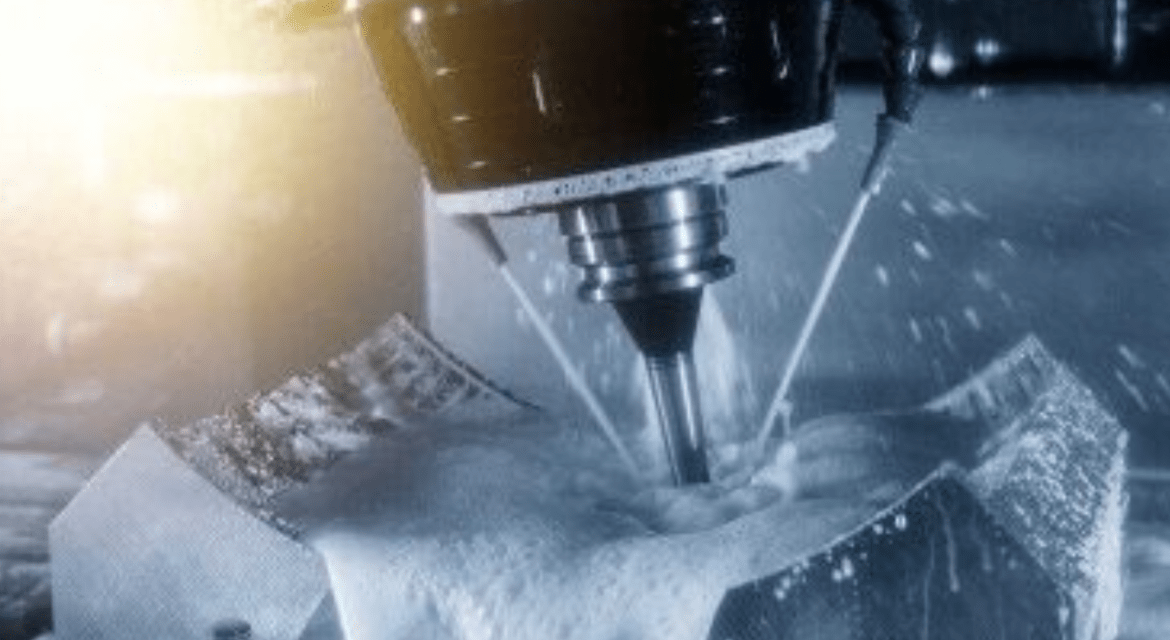

The forging method of aluminum enhances its mechanical homes, together with durability and fatigue resistance. It allows for precision and flexibility in product design through the use of strategies like closed-die and open-die forging.

Because of its power, lightweight, and power efficiency, cast aluminum has many uses within the enterprise, enhancing performance in transportation, creation, and different sectors at the same time as assisting an extra environmentally pleasant footprint. Here is the link https://www.cxinforging.com/maximizing-durability-the-advantages-of-forged-aluminum-in-industry/ which we can visit to get the information about the forged aluminum and its uses.

Benefits of Forged Aluminum

It is also lightweight. Forged aluminum offers several distinct advantages in business programs, making it a favored fabric preference for crucial components across diverse sectors.

From aerospace to automotive industries, and even in customer items, forged aluminum provides precise advantages that contribute to overall performance, performance, and sturdiness. Here are the key benefits of forged aluminum in the industry:

Energy-to-Weight Ratio

Forged aluminum possesses a brilliant power-to-weight ratio, making it one of the strongest metals used in industrial applications at the same time as final lightweight. This characteristic is specifically tremendous in industries in which lowering weight is critical without compromising power and structural integrity. In-car programs, forged aluminum components consisting of suspension components and wheels make contributions to reducing overall automobile weight, improving fuel performance, and enhancing coping with and overall performance.

Improved Mechanical Properties

The forging method enhances the mechanical residences of aluminum using aligning the grain shape to follow the form of the part. Cast aluminum exhibits higher tensile energy in comparison to cast or machined components of the same alloy, making it appropriate for packages requiring sturdy structural assist. The subtle grain structure of solid aluminum complements its fatigue resistance, making sure reliability beneath cyclic loading conditions.

Corrosion Resistance and Surface Finish

Aluminum evidently paperwork a defensive oxide layer whilst exposed to oxygen, which complements its corrosion resistance. solid aluminum components undergo extra floor remedies or coatings to in addition improve their corrosion resistance, making them suitable for difficult environments. Components utilized indoor systems and systems enjoy the inherent corrosion resistance of forged aluminum, reducing renovation and lengthening provider lifestyles.

Precision and Dimensional Stability

Forging allows for the specific shaping of aluminum components with tight dimensional tolerances and a terrific floor finish. Forged aluminum elements can obtain complicated shapes and configurations that are difficult to produce through different production methods. This precision is vital in aerospace and automotive industries for aerodynamic efficiency and structural integrity. Components are synthetic through forging to hold dimensional balance and uniformity, ensuring compatibility and simplicity of assembly in complicated systems.

Value Performance and Sustainability

Whilst initial tooling and setup charges for forging may be higher compared to casting or machining, cast aluminum offers long-term period cost performance and sustainability blessings. Forging minimizes material waste because it makes use of raw cloth greater correctly compared to different production procedures. This reduces overall material expenses and supports sustainability tasks.

Concluding Words

Forged aluminum offers extensive benefits and those make it a versatile cloth choice for crucial applications throughout industries in which lightweight, durable, and excessive-performance components are critical. By leveraging the precise residences of solid aluminum, industries can obtain stepped-forward performance, reliability, and durability in their products even as they assemble stringent overall performance necessities and sustainability goals.