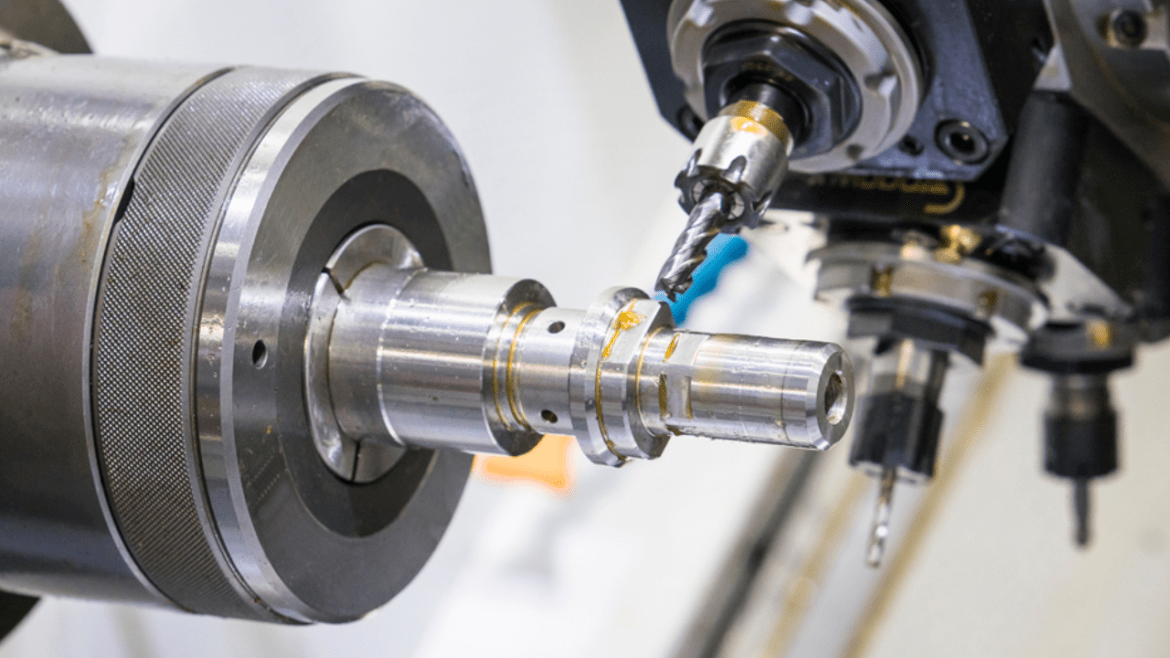

The automation of machine tools through the use of computers carrying out pre-programmed sequences of machine control commands is known as computer numerical control (CNC). Contrast this with machines that are mechanically mechanized by cams alone or manually operated using levers or hand wheels. In the CNC machining process, production equipment and tools are moved according to pre-written software for computers.

A single set of instructions can be used to execute three-dimensional cutting jobs. When a cnc turning services the planned cuts are programmed into the software and supplied to the appropriate tools machinery. Which do the prescribed dimensional jobs in a manner similar to a robot.

Benefits of CNC Precision Machinery

For machining to be both efficient and of high quality, precision and repeatability are essential prerequisites. Generally speaking, CNC precision machining shines in a number of ways to support meeting performance and quality requirements. Some benefits of CNC machinery are given below:

Modern Machining Technology

The accuracy a cutting-edge technology that adheres to industry 4.0 requirements is CNC machining machinery. It removes the need for extra labor and runs large gear. Computer programs now enable the automation of the majority of tasks, regardless of the CNC machine tool utilized. They are “live operators” who work with cutting instruments to form various raw materials into desired finished goods.

Boost Reliability and Performance

While certain applications don’t require precise tolerances, others can accept the results of traditional machining. These specifications necessitate extremely precise machining. Additionally, most industries frequently need a lot of the same items. Only the repeatability of precise CNC machining makes this feasible. With CNC machines applying comparable cuts and maintaining uniform quality on all parts, quality processes are constantly in place.

Reliable Part Quality

The level of CNC precision machining is unparalleled. Because computer numerical control is used, any variation present in traditional machining is eliminated. With little maintenance and cutting-edge software to match design requirements, the procedure can last for several hours Because of this, even the most complicated parts may be produced using cutting-edge techniques to guarantee the highest quality that surpasses client expectations.

Reduced Cycle Time and Cheap Labor

Due to its improved machining automation and programming capabilities, CNC precision machining can satisfy increasing production demands without causing machine downtime. High-precision machines are made to be extremely accurate and to produce results that can be repeated.

However, manual monitoring and alterations of the tools and operating rates are necessary for conventional machining. On the other hand, a CNC machine may execute offline programs. One machine operator can manage multiple productions while switching between machining centers. The operator performs offline debarring, quality control, and maintenance on load parts and tools.

Tight Tolerance

The main justification for using precision CNC machining is tight tolerances. Precision in dimensions is another name for tolerance. It alludes to a little difference in a machined part’s size from its CAD drawings. Tolerances are minimized as much as possible through the use of specialized techniques and cutting equipment in CNC precision machining. Compared to the original plans, this results in parts that are more accurately manufactured.

High Repeatability

One of the key cornerstones of contemporary manufacturing sectors is the idea of repeatability. To the end user, every component produced by a process is supposed to look exactly like every other component. Any departure from this reproduction is frequently regarded as a flaw. In this sense, precision machining is appealing. Every component made using a high-precision CNC machining process is nearly identical to the original.

Safety

A CNC machine removes the possibility of human error in the cutting processes by substituting computer numerical control systems for human labor. Workers may be moved into positions requiring greater skill sets, such as CNC design work.

Summary

There is no doubt that CNC machines generate more accurate products. CNC precision machines offer a lot of benefits. However, the success of your CNC milling project mostly depends on the engineers, technicians, and operators of the CNC milling machines, much like with other machining technologies. You must therefore choose the best manufacturer for your project.